The 2025 edition of the Propliner Annual will be published in late April 2025. As its title implies, Propliner Magazine is totally dedicated to Propliner aircraft and is a must-have for any aviation enthusiast and especially Propliner enthusiasts. Orders for this bumper 176-page publication can be placed at www.propliner.co.uk

The 2025 edition of the Propliner Annual will be published in late April 2025. As its title implies, Propliner Magazine is totally dedicated to Propliner aircraft and is a must-have for any aviation enthusiast and especially Propliner enthusiasts. Orders for this bumper 176-page publication can be placed at www.propliner.co.uk

Super Connie Waiting for a New Owner - May 11, 2025

Peter Brill recently posted a friend's photos on Facebook of Super Constellation HB-RSC. The aircraft sold to German investment group July 1, 2019 with the goal of restoring airworthiness of aircraft and, after disassembly in August/September 2019, it was moved by road to Eschbach-Bremgarten in southwestern Germany on November 27, 2019. The original plan was for Meirer Motors to spearhead the project but somewhere along the line the effort was abandoned and the aircraft was first advertised for sale in April 2023. Peter's post "Some new photos of HB-RSC c/n 4175 in its dismantled state at Meiermotors. Professionally dismantled and stored under cover, this project is for sale." Many thanks to Peter for posting the report and photos.

|

|

|

|

|

|

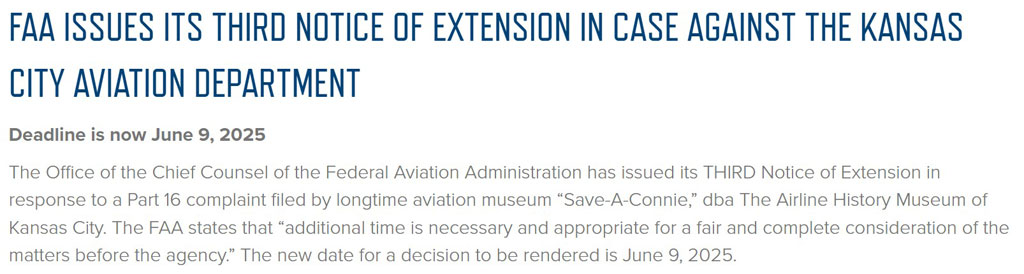

FAA Kicks the Can Down the Road on AHM's Part 16 Complaint - April 16, 2025

The Airline History (AHM) recently announced on its website that the FAA has once again issued an extension on the museum's Part 16 Complaint with the new decision date being June 9, 2025.

In related news, on December 4, 2024 I reported that an organization calling themselves the "Kansas City Aeronautical Museum" were pursuing establishing a museum in Hangar 9 with many of the AHM exhibits. I recently heard that the organization has abandoned its quest due to the ongoing Part 16 complaint, which could possibly take years to wind its way through the FAA bureaucracy and the courts.

Three Super Constellation Fuselage Sections Offered for Sale - March 25, 2025

Three former military Super Constellation fuselage sections have been offered for sale today on the Barnstormers.com website.

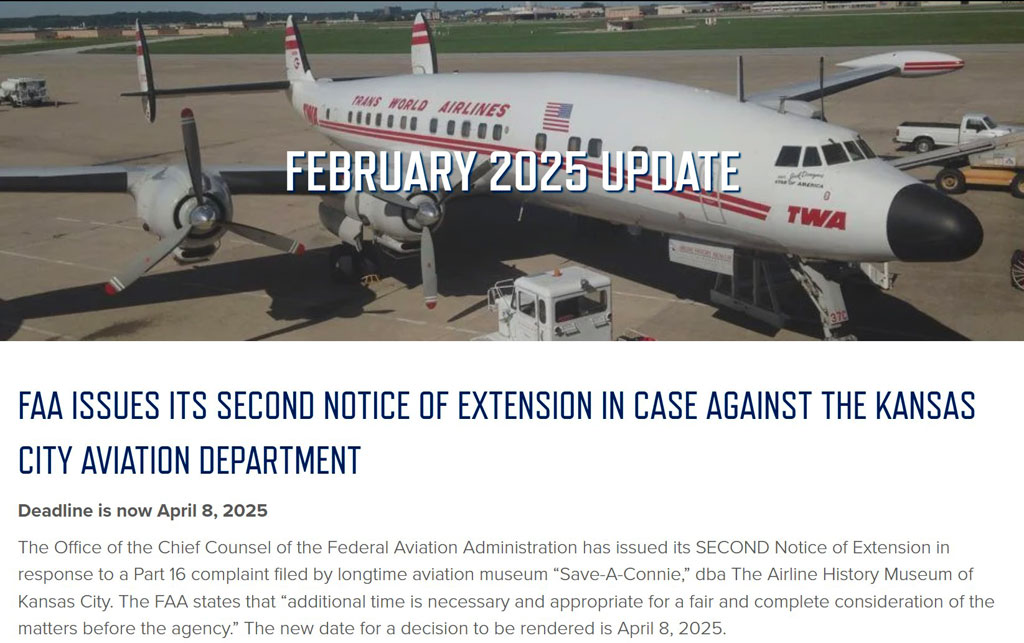

AHM Announces a Second Notice of Extension by the FAA re the Museum's Part 16 Complaint Against the Kansas City Aviation Department - February 11, 2025

As reported on November 21, 2024, the Airline History Museum filed a Part 16 complaint against the Kansas City Aviation Department. The complaint was filed on September 4, 2024, with a decision due from the FAA on December 10, 2024. This was extended to February 7, 2025 and the Airline History Museum recently announced on its website that it has been extended again to April 8, 2025.

Lufthansa Technik Issues Statement re Starliner Rollout - January 18, 2025

Lufthansa Technik issued the following statement re the rollout on LinkedIn

A Milestone in Aviation History

Today marks a significant milestone as we together with Lufthansa Group proudly unveiled the meticulously reassembled Lockheed L-1649A Super Star at our Hamburg headquarters. For the first time in decades, this iconic long-haul aircraft rolled out of the hangar on its own landing gear and onto our apron - a moment of aviation nostalgia igniting widespread excitement.

An interdisciplinary team of around 15 mechanics, spanning multiple generations, worked tirelessly over the past year to bring this aircraft back to beauty. Their expertise and dedication made the precise reassembly of large components - like the fuselage, wings, and the iconic triple tail unit - a reality. In October 2023, these components arrived in Hamburg, along with 292 wooden crates of smaller parts.

One standout feature of this non-airworthy reassembly is the cockpit, restored as faithfully as possible to its original 1950s condition. The lighting and controls are fully functional, and cable pulls make the rudders and flaps movable - a tribute to the exceptional engineering of its time.

In 1957, the Lockheed Super Star flew the connection to New York non-stop across the Atlantic. The aircraft was therefore a technical masterpiece of its time. With its four piston engines, it closed the chapter of classic propeller-driven aircraft on the North Atlantic routes. These flights, which lasted up to 17 hours, took off from Hamburg, where the maintenance base was also located. The roll-out therefore took place at a location of equal importance to Lufthansa and Lufthansa Technik.

Reassembled Starliner Emerges From Hangar - January 17, 2025 - Updated January 20, 2025

L1649A N7316C (D-ALAN) was rolled out of a Lufthansa Technik hangar at Hamburg Airport today after reassembly by Lufthansa Technik staff and retirees. It was moved to Hamburg in October 2023 and on April 12, 2024 Lufthansa announced that the aircraft and Ju52 D-AQUI would be placed on display in Frankfurt at a dedicated visitor and conference center. Construction is scheduled to be completed in 2026, just in time to celebrate the 100th anniversary of the airline. Dirk Grothe captured some great photos today of the aircraft emerging from the hangar and forwarded the following report and photos.

A milestone in aviation history is being shown to the public for the first time: Lufthansa Technik has completed the extensive assembly of a Lockheed L-1649A. The fully restored long-haul aircraft was pulled out of the hangar on its own undercarriage for the first time and thus experienced its roll-out in Hamburg - a moment that not only thrilled aviation enthusiasts.

Former N7316C (c/n 1018, delivered 1957 to TWA and last flight on 09.11.1983) has been under restauration by Lufthansa since 2008 in Auburn (Maine, USA) to restore it in an airworthy condition for future flights until the project was stopped in 2018 after 10 years and 150 Million Euro costs and the aircraft was shipped to Bremen/Germany in 2019. It was transferred to Paderborn in February 2021 and to LH-Technik Hamburg in October 2023.

The aircraft was purchased by Deutsche Lufthansa Berlin Stiftung in 2007 together with N8083H (c/n 1038 former TWA) and N974R (c/n 1040 former LH D-ALAN).

Following the roll-out, the aircraft will be dismantled into larger segments again in the coming weeks, before being transported by heavy transport to Munster/Osnabruck Airport in July. There, it will be painted in Lufthansa's original design from the so-called parabolic phase. After painting, the Lockheed Super Star is scheduled to arrive in Frankfurt in October. Just in time for Lufthansa's 100th anniversary, from spring 2026 it will be the main attraction of the Lufthansa Group's new conference and visitor center beside the Lufthansa Aviation Center at Frankfurt Airport, together with the legendary Junkers Ju 52 D-AQUI. Thanks to a glass facade, the exhibits will also be clearly visible from outside.

|

|

|

|

|

|

|

|

|

Kansas City Super Connie Engine Runs - January 12, 2025

As reported on November 1, 2024, Super Connie N6937C was acquired by John Travolta's production company Constellation Productions Inc. in September 2024. After some TLC by mechanics, the aircraft emerged from Hangar 9 at Kansas City Downtown Airport yesterday for some engine testing. All four engines successfully ran and the aircraft taxied around the ramp before heading back to the hangar. Archie Dinwiddie photographed the aircraft and recorded some videos, which he posted on the Lockheed Constellation Facebook page. Many thanks to Archie for sharing his photos and videos.

|

|

| Page Top | Home |

----Created 31 January 2004------Updated 11 MAY 2025----